Conduit for Learning

Electrical engineering interns assess the campus power grid.

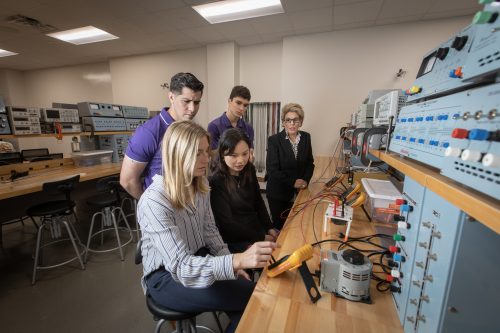

TCU engineering students got practical experience by assessing campus power quality. Touring TCU’s east chiller plant were, from left, Samuel Busa, Chelsea Boh ’23, professor Morgan Kiani, Nhu Le and Daniel Lopez ’23. Photo by Rodger Mallison

Conduit for Learning

Electrical engineering interns assess the campus power grid.

In 2022, TCU’s campus — with a population of 13,500 students, faculty and staff — used more than 90 million kilowatt-hours of energy. The average American household, in comparison, consumed about 11,000 kilowatt-hours.

To keep its energy needs from growing exponentially as the campus and enrollment expand, TCU updates its buildings with energy-efficient lighting infrastructure, video displays, kitchen utilities, and computers and server rooms that power a 21st-century education.

While the upgrades ensure access to the latest technologies, these new devices are running into compatibility issues with the campus power grid. What flows through the outlets does not always allow the technology to operate at full efficiency.

The university’s power grid is not bad. In fact, Kellen Dean, manager of the electrical and fire systems, said TCU’s grid is incredibly advanced — “probably better than most military bases around the world.”

To fix the efficiency issues, he said, TCU needs to identify and mitigate problems affecting campus power quality.

The Quality of Power

Power quality is the compatibility between the voltage that comes out of an electrical outlet and the power load plugged into it. A power load is any individual electrical device, such as a TV or microwave, that needs to be plugged into a larger power grid to operate.

Different devices require different wattages to run at full efficiency. And while TCU’s electrical systems may be capable of handling newer power loads, the grid is set to work with older devices.

Morgan Kiani, professor of engineering, said that old and new devices differ in how much electricity they consume, as well as in the thermal energy they create as a byproduct.

“Older devices change electricity more often to heat,” Kiani said.

Take the light bulb: Older incandescent bulbs work by using electricity to superheat a filament of tungsten, which then emits light.

Today’s LED lights use a microchip with a single light-emitting diode, hence the name LED. The diode directly converts electrical energy into light, bypassing the heat stage. This allows the LED light to be up to 90 percent more efficient than a standard incandescent bulb while still producing the same amount of light.

Because newer technologies more efficiently convert electricity into the desired function — sound, heat, light, etc. — the devices require less energy to operate.

But this also means that these newer devices are not well equipped to handle the high-energy outputs from an older grid. They soak up more power than what is required for them to operate, which results in poorer power quality.

“If you are in a building with poor power quality,” Kiani said, “it is going to affect your electrical appliances like computers and refrigerators and wear them out more often.”

A Chance to Learn

Before 2021, no studies had measured the power quality of TCU’s energy grid with existing technologies. With the help of Baird Hampton & Brown, a Texas-based engineering and surveying company, Kiani and Dean formed a research team composed of TCU engineering professors, seasoned electricians, experts from the firm and students in the College of Science & Engineering.

Team members installed monitoring equipment in buildings across campus, including the TCU Campus Store and the Sid Richardson Building, to evaluate power quality.

“Our research is bringing power quality up to TCU’s attention,” Kiani said. “We are showing them that we have to update our systems to make sure our technology works in harmony.”

Students like Chelsea Boh ’23 operate electronic test equipment in an engineering lab, work that helps them learn about the TCU power grid. Photo by Rodger Mallison

The project, conducted in the summers of 2021 and 2022, was not just about improving TCU’s power quality: Its primary purpose was as an internship program.

“The students are the key point of this program,” Dean said. “Everything that we are doing now is to help the next generation.”

Students used the tools of the field in real-life settings while also learning how the data gathered by those tools help construct solutions for 21st-century electrical problems.

The internship launched in summer 2021 with its first student, electrical engineering major Thang Hai Nam Au ’22. During his time with the research team, Nam Au, who is now pursuing a doctorate in Minnesota, learned how to install and maintain the equipment the team used to measure the Campus Store’s power grid.

“I had to wear full protection to start measuring the electrical data,” Nam Au said. “I did not have that kind of experience back in classes, so it was valuable to personally see how the safety procedures are done.”

To measure power quality, Nam Au used a Fluke 435-II to assess the Campus Store’s power distribution system. He helped evaluate the readings to identify the areas in the grid where the power supply did not match modern power load demands. He then developed proposals to improve campus power quality.

Grounding for the Future

Dean and Kiani’s research team has come up with several ideas on how TCU’s grid can meet today’s power demands.

One long-term solution is to install equipment that will give the campus’s energy grid the ability to adjust to the demands of new power loads as they are plugged in. These devices, called capacitors, would be added to the power lines that run throughout campus. They work by reducing the amperage going through the cables, which results in less energy loss.

Morgan Kiani, professor of engineering (right), said research done by the College of Science & Engineering “is bringing power quality up to TCU’s attention. We are showing them that we have to update our systems to make sure our technology works in harmony.” Photo by Rodger Mallison

“By using these capacitors,” Kiani said, “we can make sure the power quality for the whole building is as close to the optimum as possible.”

This adaptability will improve the longevity of the electrical equipment and devices, both new and existing, across campus. It will also substantially decrease the electricity consumed on a daily basis, shrinking the university’s carbon footprint as well as its utility bill.

Kiani and Dean are also pushing to introduce more renewable power sources to campus. One proposal is to install solar-powered charging stations for the fleet of electric golf carts. They also hope to install a solar array on campus to reduce TCU’s reliance on electricity from the public grid. The primary obstacle is finding the hundreds of square feet required to build such a large system. Putting solar roofs on parking garages could be a potential solution.

No matter the outcomes, the research has proved a boon for both the students and the university as a whole.

“The students benefit by experiencing the things they are studying about through practical application,” Dean said, “and TCU gets to benefit from it by making nuanced changes to our power system.”

Your comments are welcome

Comments

Related Reading:

Features

Infographic: Minors

A wide variety of minors gives TCU students the chance to add depth to their majors or dive into new areas.

Features

Venture Capitalism 101

MBA students connect investors and startups in a Neeley program.