Failure on a Small Scale: Tiny Holes Elude Silicon Researchers

Professor Jeffery Coffer doesn’t allow frustration to get in the way of solving a riddle.

Failure on a Small Scale: Tiny Holes Elude Silicon Researchers

Professor Jeffery Coffer doesn’t allow frustration to get in the way of solving a riddle.

Jeffery Coffer remembers how his doctoral adviser broke the news: “All the easy research problems have been solved. Only the hard ones are left.”

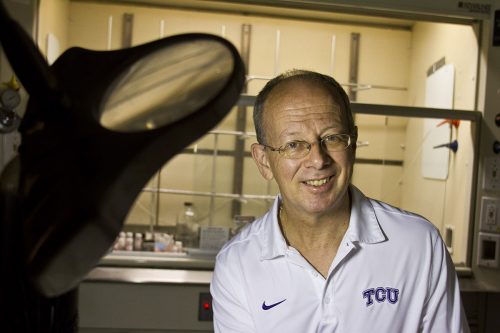

Professor Jeffery Coffer said research is about taking smart risks and pushing through. Photo By Mark Graham

Coffer, professor of inorganic and materials chemistry, accepted the challenge.

After setting up a research lab at TCU in 1990, Coffer jumped into the rabbit hole otherwise known as porous silicon. About the same time, scientists found that when the second-most common element in the Earth’s crust is imbued with holes, it emits light.

The professor split his research time between the low-risk projects — experiments in the light-emitting variety that should yield results — and less attainable dreams of the better-living-through-silicon variety.

In terms of usefulness, silicon is just getting started. When imbued with infinitesimal nanoholes, silicon could revolutionize drug delivery, increase battery storage capacity, and improve solar panels and lighting systems.

But for researchers to explore those possibilities meant venturing into the dark unknown, and the path could lead nowhere. Devoting time and money to scientific inquiries with no definite outcome is “like investments,” Coffer said. “You always hedge your bets a little bit.”

Why Bother?

For years Coffer and his lab assistants had been perfecting the process of creating nanoholes (about a billionth of a meter) in silicon “rocks” by dumping the particles in acid and running an electrical current through the mix.

Those resulting holes can be packed with even tinier substances, including medicines. In current pill form, medicines cause side effects because to sustain delivery over time, the initial chemical flood overshoots the ideal dosage. The chemicals rush into the bloodstream in high amounts so they can later taper off and last as long as advertised. But that initial spike in medicine can cause side effects.

To fix the problem, Coffer said, “You take a little bit of drug and you just release it over long periods of time. That’s called sustained delivery.”

One method of the long release is to fill holey silicon with medicines and let them drift into the bloodstream at a slow and steady pace. Coffer’s tiny silicon rocks, while a promising step, were about as uniform as a field of boulders. Not ideal for precise dosing.

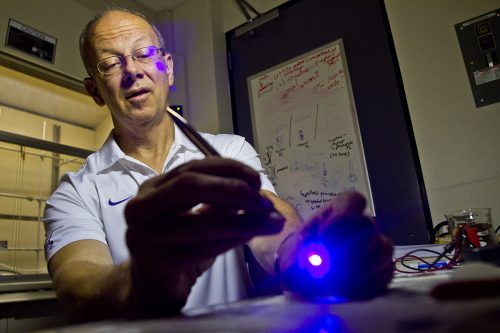

Jeffrey Coffer, professor of chemistry at TCU, worked for years trying to find a way to “etch” holes in silicon materials to allow such things as drugs to be packed into them for delivery to the body. Photo by Mark Graham

A surer side of his lab research, the safe investment, led to the construction of silicon nanowires, as tall as a human hair is wide, which could be engineered to precise proportions. Coffer decided to try to etch holes into the surfaces of those wires. That could maximize precision — an important consideration when exact doses are the goal.

“Etch holes into the wires, right? Sounds like a good idea,” Coffer thought at the time.

Scott Dunkle ’05, then an undergraduate student in chemistry, was exposed to the rigors of scientific research about the time Coffer’s nanowires and nanoholes became interrelated objectives.

The plan sounded like a good idea to him, too, Dunkle said. “You think scientists are smart and things work most of the time.”

The experiments Coffer and his team attempted didn’t work. At all.

“We spent literally from 2002 to 2008 — about six years — trying to etch holes into wires,” Coffer said. “We tried all the strategies.”

The electrical currents didn’t work. No proven methods of etching holes into substances were effective. Every attempt resulted in a “total collapse” on the nanowire, Coffer said. “It was like the Tower of Babel.”

Why? “We forgot about gravity.”

A Happy Accident

Xuezhen “George” Huang ’10 PhD spent seven years in Coffer’s lab. His main task was to make silicon nanowires glow brighter. He had been spared the constant dejection of trying to create holes on those wires.

For months, Huang attempted to coat the wires with titanium, but that wasn’t working either. The coating wouldn’t stay solid when he added other chemicals. He felt he was ruining the wires. He presented the results to Coffer along with an apology.

But Coffer smiled and paused. Huang, who now works to improve lithium ion batteries, didn’t know the failed experiment caused his mentor’s mental wheels to turn. Perhaps the coated wires could be dissolved in patches by the same chemicals, which might then eat the silicon away, too.

Coffer asked Huang to try the new approach.

The new tactic worked, and at long last, the wires, which had by then been expanded to tubes, were covered in holes. Success sprang from trying new things while remaining focused on the end goal, Coffer said. “The old strategy [wasn’t] going to work. … You have to be open to new ideas.”

The belief that experience equals wisdom can lead a scientist astray, Coffer said. “We become enamored with our own little ideas, our pet concepts or pet hypotheses, and it’s easy to not listen to new ideas.”

The Future Is Silicon

Failure, in the science lab, isn’t an outcome to avoid but rather “an indelible part of the process,” said Stuart Firestein, a professor of biology at Columbia University who wrote Failure: Why Science Is So Successful (Oxford University Press, 2015).

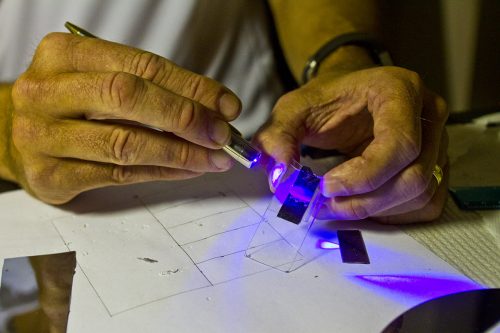

Jeffrey Coffer, professor of chemistry at TCU, shines a laser pointer onto a piece of film to show the silicon nanoparticles. The bright area with red is the reflection of the nanoparticles on the film. Photo by Mark Graham

“If you succeed all the time, it’s like a coin coming up heads too often. Your work may become suspicious,” Firestein said. Thus, scientists would be wise to befriend failure. “You do have to develop a little bit of a thick skin, if you will.”

Coffer made pals with failure during a long series of failed experiments. “We got to that technology [silicon nanotubes] basically because we got frustrated for six years,” he said. “Ultimately the frustration led to success.”

Now that they exist, the possibilities of porous silicon nanotubes are endless. In addition to medications, those nanotubes can be packed with magnets and medicines for targeting a specific location in the body. They can make LED lights brighter and they can make batteries more efficient, just to name a few possibilities.

Dunkle applies those early research frustrations to his job as an environmental risk manager at the University of North Texas. In Coffer’s lab, he said, “I truly first started to learn how to think, started to learn how to solve problems and that everything isn’t cut and dry, and everything isn’t written out, prescribed for you. You’re trying to push the envelope and you’re trying to do things that no one knows the answers to.”

Research is about taking smart risks and pushing through, Dunkle said. “You certainly get more failures than you get successes, which makes the successes much more sweet.”

Coffer said success flows from a willingness to persist in the face of difficulty: “Don’t give up on an idea just because it’s not working.”

Your comments are welcome

Comments

Related reading:

Features

Did you Fail? 7 Frogs Find Meaning in Life’s Wrong Turns

On the path to success, falling doesn’t mean you can’t fly.

Letters

College Is All About Learning from Mistakes

You might have read or heard this popular story about failure. As a young man, Walt Disney was fired from a Missouri newspaper. An editor told him he “lacked creativity.”

Campus News: Alma Matters

Does Failure Have Benefits? Faculty Discuss

Professors quote notable people like J.K. Rowling and Jimmy Buffett to reflect on the fruits of failure.